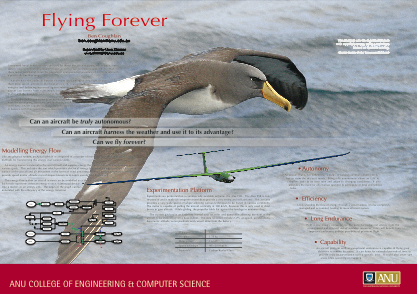

I’ve fallen back into hardware mode before making any significant progress recently. I have to say I enjoy it more, and I do have so much hardware to come up with for the Outback Challenge.

The last week has been focused on antenna tracking. Basically I have two large yagi antennas that I need to keep pointed at the aircraft which requires a pan/tilt head mounted on a mast.

The last week has been focused on antenna tracking. Basically I have two large yagi antennas that I need to keep pointed at the aircraft which requires a pan/tilt head mounted on a mast.

The antennas are quite large, weighing about 4.3Kg total and being about 2m long. I’d also like the mount to be stable enough to mount a camera with a suitably large lens. Having something automatically record the aircraft will make documentation much easier.

This puts me in an awkward range in terms of pan/tilt heads. The options either seem too light and under-powered, or prohibitively expensive.

This puts me in an awkward range in terms of pan/tilt heads. The options either seem too light and under-powered, or prohibitively expensive.

Not considering the tiny, point-and-shoot camera variety; the affordable end of the scale looks to have two serious options (although if there are any out there I have missed I would love to know about them).

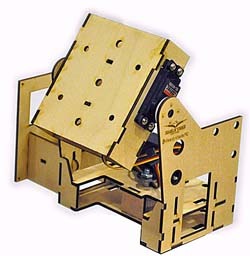

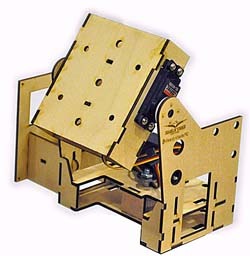

The most popular in the FPV community seems to be this thing, annoyingly unnamed. Made from laser cut wood it is more than capable of swinging a single patch antenna around, but will definitely struggle under my yagis.

It’s nice and cheap at $90 including servos.

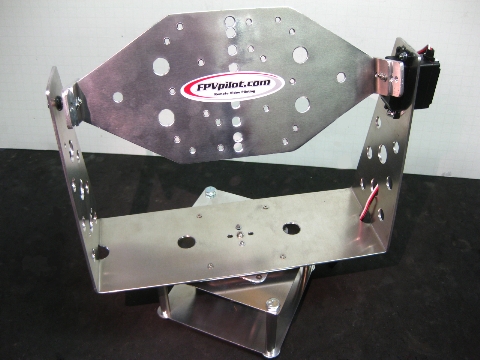

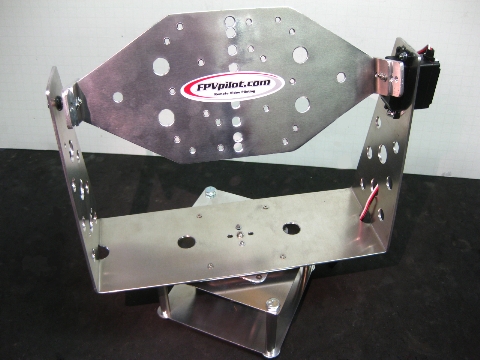

The pan/tilt head closest to my specs is the AT Pro-1000. This is made completely of aluminium and when using the supplied HS645MG servo on the tilt axis there is plenty of torque, about 9.5Kg.cm.

The main drawback of this design is that it is definitely aimed at patch antennas, with large, wide structural members. They do provide a bracket for mounting a single, smaller yagi, however getting both of my antennas on there will be awkward.

AT Pro-1000The AT Pro-1000 weighs about 1Kg and is roughly 30cm wide. It’s price point is almost exactly where I am looking at $220 including servos and yagi bracket.

AT Pro-1000The AT Pro-1000 weighs about 1Kg and is roughly 30cm wide. It’s price point is almost exactly where I am looking at $220 including servos and yagi bracket.

So it seems easy enough to swing patch antennas around. Unfortunately patch antennas don’t offer the gain or the focus of a large yagi. Outback Joe didn’t exactly get lost in a convenient place and maintaining comms is pretty critical.

The other end of the scale comes with incredible specs and some pretty fantastic features. It also comes with a bunch of request for quote forms…

D48ESomething like the D48E or even it’s smaller cousins would easily meet my needs, and then some.

D48ESomething like the D48E or even it’s smaller cousins would easily meet my needs, and then some.

Capable of swinging over 10Kg around at 100 degrees per second (probably not at the same time) and incredible 0.003 degree tilt resolution.

The offerings from FLIR also boast ethernet integrated and all weather operation.

These are actually available from distributers in the US and Canada, but even the smallest was well over $2000. Far beyond my budget, and requirements for that matter.

The one major difference is the design. The D48E has more uses in mind than just patch antennas and so only offers a single mounting bracket for any accessories, making it easier to mount custom hardware.

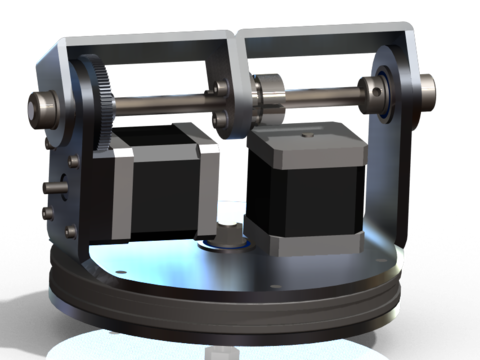

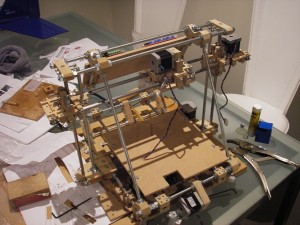

So like most of my product searches recently, I’ve resolved to design and build one myself. I’d be lying if I said I was disappointed 😛

Over the last week I’ve been madly scheming and searching the interwebs for suppliers and I think I’ve gotten to a draft I can actually build in my garage.

I originally wanted to use 6mm steel plate to ensure it was strong and rigid. I eventually realised that my tools are not up to steel, especially if I were to try hot-forming the bends. I considered having someone machine the steel for me but decided that I didn’t really need steel at all.

To simplify things a few orders of magnitude, I decided on 6060/1 aluminium in stock extruded channel. Aluminium is much easier to work with the in the backyard, and using stock in the right shape meant that my job was already half done.

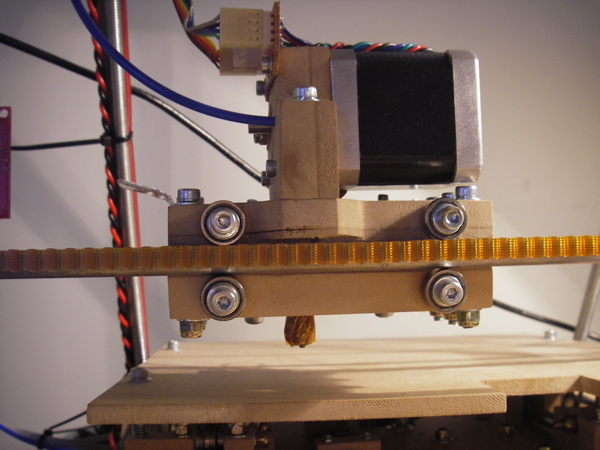

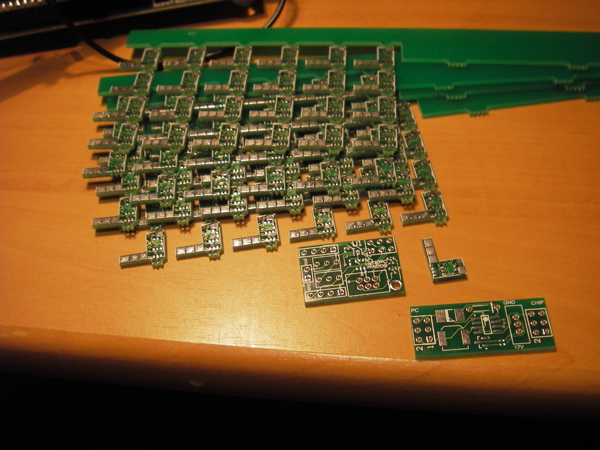

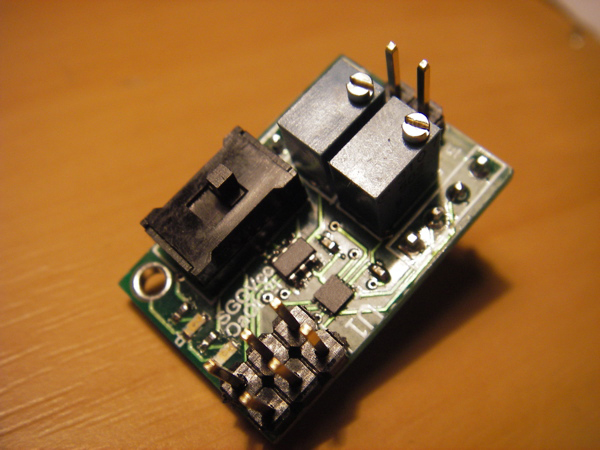

At the moment I’m trying to decide between servos or stepper motors, and where to find the cheapest parts ($50 for that hub in the middle! seriously!) but the shape is pretty much fixed. The antennas will mount towards the ends of a bar bolted to the top face.

The base diameter is 150mm and sits completely on a custom bearing, so there should be very little wobble. I’m aiming to keep the entire cost below $300.