It’s been a while since my last post. This is because I’m halfway through several projects and I’ve been trying to actually get something finished to write about. Failing that, I think I’ll bundle a bunch of updates into this post.

RepRap

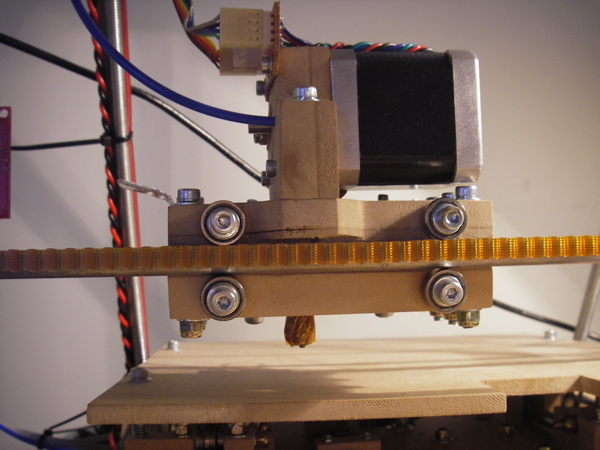

The extruder fitted to the printerKapton tape finally arrived on my doorstep the other week. This has allowed me to complete the extruder, giving me a complete Mendel! 😀 It appears to work in that it gets hot enough to melt the plastic I poked it with… I’m not really sure how accurate the temperature measurement is, as MakerBot doesn’t provide any technical data about the thermistor they stock. So providing the right temperature tables is a bit tricky.

The extruder fitted to the printerKapton tape finally arrived on my doorstep the other week. This has allowed me to complete the extruder, giving me a complete Mendel! 😀 It appears to work in that it gets hot enough to melt the plastic I poked it with… I’m not really sure how accurate the temperature measurement is, as MakerBot doesn’t provide any technical data about the thermistor they stock. So providing the right temperature tables is a bit tricky.

Now I’m spending my time working out the various software tool chains available. The main choice is between the RepRap host software and ReplicatorG. I played around with each of them a little and their associated firmware. The main difference between them is that the RepRap software implements a 5 dimensional G-Code interpreter where ReplicatorG controls the tool speed directly. The 5D GCodes are much closer conceptually to the actual outputs of the printer, and I see that as the better method. However, the RepRap implementation leaves a bit to be desired. ReplicatorG is based on Processing so the GUI is much more stable and intuitive. I also found the firmware, while it has less features, is also a little more robust. So I’m ‘moving forward’ with ReplicatorG, and will likely have a number of contributions to make.

The main thing ReplicatorG is missing is support for the Mendel, as it’s primary focus is the CupCake CNC. The work around to get the stepper extruder working with the 1.x build wasn’t very satisfying. I’ve added support to the 2.x branch and it seems to work. Unfortunately, early in my experimenting with the firmware, one of my H-Bridges exploded rather spectacularly leaving my printer crippled. A replacement will be arriving tomorrow so I can do some proper testing. I’ll put my code up along with some explanation and howtos once I’ve tested and figured out a working Skeinforge profile.

Servo

I think it’s looking realistic enough now that I’ll give it a short mention here. I’ve been working on a new servo design intended to fit in the very thin wings of a scale glider. The main design goal was to keep it under 6mm thick, which I’ve managed to do. Depending on a few remaining design decisions, I think I can get it down to 5mm thin.

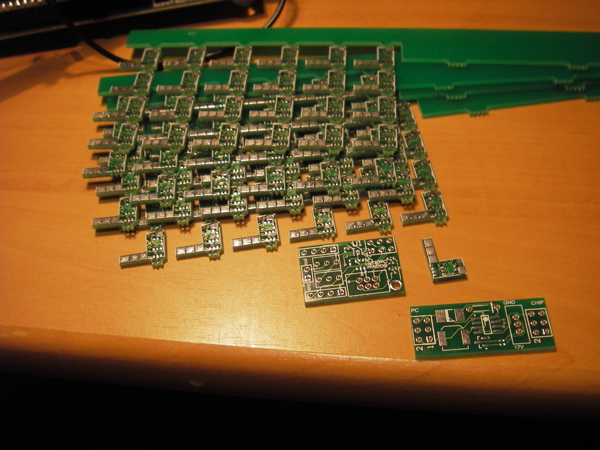

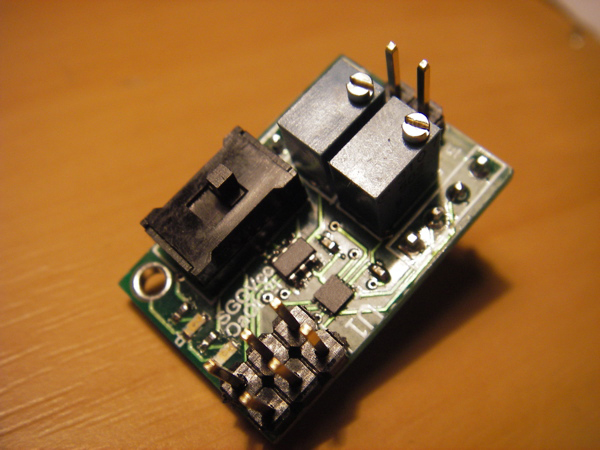

I think it’s looking realistic enough now that I’ll give it a short mention here. I’ve been working on a new servo design intended to fit in the very thin wings of a scale glider. The main design goal was to keep it under 6mm thick, which I’ve managed to do. Depending on a few remaining design decisions, I think I can get it down to 5mm thin. The development version of the servo controllerThe prototype PCBs arrived this week which I was very excited about. I have Ben at Nias Digital to thank for getting them manufactured. I’ve populated one of the broken-out versions so I can start testing the firmware. This involved a lot of time with a scalpel and a pin followed by some frying pan reflow due to my lack of expensive equipment, and the need to use 0402 sized components. It came out well however, and initial testing has been positive.

The development version of the servo controllerThe prototype PCBs arrived this week which I was very excited about. I have Ben at Nias Digital to thank for getting them manufactured. I’ve populated one of the broken-out versions so I can start testing the firmware. This involved a lot of time with a scalpel and a pin followed by some frying pan reflow due to my lack of expensive equipment, and the need to use 0402 sized components. It came out well however, and initial testing has been positive.

More on this one later 🙂

I’ve been having the same trouble with trying to get the gen3 boards from techzone up and going inside replicatorg. I tried to take the 5d firmware and transfer the pinouts into the repg firmware but didn’t have any luck. Any chance you can share the sketch you came up with to solve the problem.

Thanks much,

Reed

#define RX_ENABLE_PIN 4

#define TX_ENABLE_PIN 16

// Pins to direct-drive the extruder stepper

#define E_STEP_PIN 10

#define E_DIR_PIN 9

#ifdef MAX6675_THERMOCOUPLE

// I2C pins for the MAX 6675 temperature chip

#define SO 18 // MISO

#define SCK 19 // Serial Clock

#define TC_0 2 // CS Pin of MAX6607

#else

#define TEMP_PIN 7

#endif

It’s still a work in progress and requires a bit of explanation. I’ll put up a full post in a day or day with sources.

The problem with the 5D firmware is that RepG can’t talk to it as they have different protocols. Hopefully someone will write 5D drivers for RepG soon, but for now I’m going to try and make-do with the Gen3 firmware.

Any luck with RepG? I’ve been working with Lambert (at TechZone) to try and figure out how to get the thermocouple working in concert with the stepper extruder. I sent the boards and motors back to him to see if he’d have any better luck getting them to work.

All the prints I’ve done have been using RepG, so the short story is yes 🙂 It was a pretty big hack though. I’ve been working at making it a bit more useful and match the RepG interface more, but haven’t had a lot of luck.

I’ve been using a thermistor rather than a thermocouple, but I believe the only difference is the requirement for the voltage divider on it’s output.