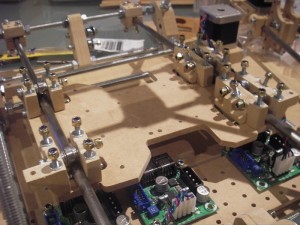

My Mendel is still progressing. I’ve recently completed the Y-Axis including the bearing mounts, chassis and print surface. The bearing are a little tighter on the rails then I would like, probably due to my laziness drilling the slots to allow for their movement. It’ll do until I print replacements.

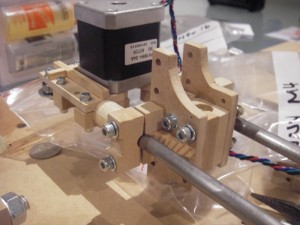

I also made the nut-jigs and nut traps the live on the ends of the X axis, so I can finally assemble them. I do still need to make the 360 bearing mounts. These bits are pretty tricky.

And finally; I’ve also made the driven gears for the bottom the lead-screws. I surprised myself with these. I certainly didn’t plan on making them when I woke up. I was considering making them from MDF like everything else, but decided they wouldn’t last very long. Instead, I ended up cutting a gear shaped hole, smothering it in vaseline (bear with me here) and then filling it with epoxy. I had very little expectation that this would actually work. MDF isn’t the greatest mould, nor is epoxy the greatest thing to mould. The results were surprisingly good!

The usual technique is to use a length of belt around the inside of the mould to ensure the tooth profile matches. I don’t have any belts yet so I’ve just used the template amongst the reprap parts.

I did just order timing belts today from Small Parts and Bearings. Their site is a little tricky, but I managed to get all the belts I need for about $45 including shipping. I’ve also got my order loaded from MakerBot to get some nichrome, thermistor, end-stops and most exciting of all: actual plastic! 🙂 I plan to find a local plastic manufacturer for a longer term supplier. Complete Plastic Welding Supplies look to be the best (only?) option. But my first batch will be a sexy blue Mendel :). I still need kapton tape, which a mate of mine says he can give me.

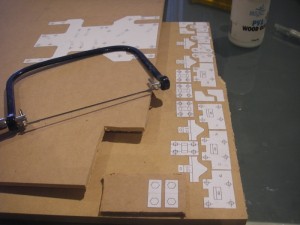

So all those bits are on their way, I just need to cut the final RP parts. I’m going to attempt all of them from MDF and have prepared all my stencils. Hopefully I’ll have them all done by Sunday afternoon, coping saw induced RSI permitting.

Um. So tried to read this and still can’t work out what you are doing…

😛 Did you have a look at the video at http://www.reprap.org“ rel=”nofollow”>http://www.reprap.org? In short, it’s a printer that creates 3D plastic objects.