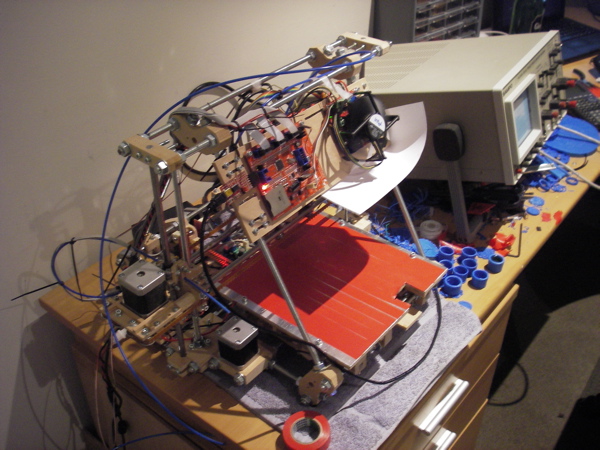

Well it’s been a very long 12 months, and I’ve spent way more cash then I intended but my Mendel is finally capable of printing stuff! Most importantly: booze proof stuff!

I’ve been obsessing with it over the past week to tweak all the various knobs in such a way that the parts come out neat enough to actually be water-tight, which has been my success criteria the whole way along.

The extruder was an absolute pain, but I’ve managed to hack it together enough that it actually runs quite reliably, just a bit slow for my taste. I’m working on a geared extruder as I type.

I also had heaps of trouble getting parts to stick, and stay stuck to the printing surface. So I hacked together a heated bed. It does very well at being warm and not catching fire, but I’m only pumping 30W into it. While this helped getting things to stick, it doesn’t stop larger parts warping and lifting off. So this weekends job is to bump that up around 100W.

I have a lot more detail to go into about these various things, and I know at least one of you is waiting on some source code (I’m getting to it :P). I’ll save these for future posts once I have some complete comments to make, rather than half finished ideas.

In the mean-time, Cheers! 🙂